Key Takeaways

- Adhesive selection greatly affects performance and safety in industrial settings.

- Advances in adhesives enable more efficient and sustainable manufacturing processes.

- Understanding the properties of different adhesives helps in matching them with specific industrial demands.

- New developments continue to drive the adhesive industry, enhancing both environmental and operational standards.

The Role of Adhesives in Modern Manufacturing

Industrial adhesives are vital in manufacturing, essential for electronics, automotive, and construction. Their strength and versatility are critical, but choosing the right adhesive requires balancing durability, usability, cost, and environmental impact. For example, when it comes to woodworking and furniture production, selecting the appropriate Eva adhesive for edge banders can dramatically improve both the quality and efficiency of edge banding operations, minimizing waste and ensuring lasting bonds.

Cutting-edge projects demand solutions that ensure strong adhesion, precise compatibility with substrates and process speeds, and compliance with safety and environmental standards. Innovations like thermoset and thermoplastic adhesives optimize productivity, performance, and cost.

Key Factors in Selecting Industrial Adhesives

Choosing the best industrial adhesive requires considering material compatibility, temperature and chemical resistance, cure time, and mechanical strength, as well as operational efficiency and safety. Different substrates and environments demand specific chemistries; quick setting adhesives can improve throughput but must also meet safety regulations. Adhesives impact product longevity, appearance, and recyclability.

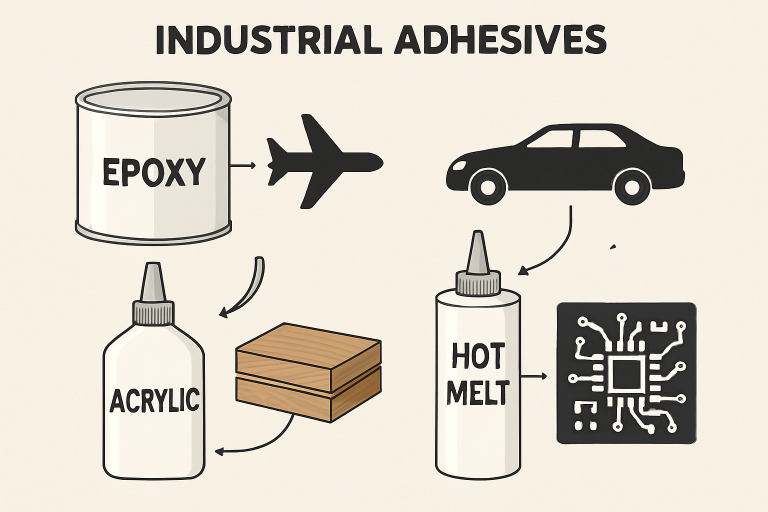

Types of Industrial Adhesives and Their Applications

- Epoxy Adhesives: Engineered for high mechanical strength and resistance to chemicals, epoxies are a mainstay in the aerospace and automotive sectors where performance standards are non-negotiable.

- Polyurethane Adhesives: Known for their flexibility, polyurethanes excel in demanding conditions where joints may experience movement or stress, making them suitable for construction and transportation industries.

- Acrylic Adhesives: Offering fast curing and superior weather resistance, acrylics have become the go-to solutions for electronics manufacturing and signage where speed and resilience are paramount.

- Hot Melt Adhesives: Hot melts, especially those based on EVA, are renowned for their rapid bond formation and ease of application, making them indispensable in packaging, woodworking, and textiles.

These adhesive categories serve specific needs, and their selection hinges on both real-world technical requirements and cost considerations. As a result, the adhesive market continues to expand with tailored solutions for evolving industrial challenges.

Sustainability: A Key Trend in Adhesive Development

As industries face mounting pressure to reduce their environmental impact, sustainability has become a driving force in adhesive innovation. New adhesive formulations are shifting towards water-based, solvent-free, or biobased systems, designed to reduce emissions, improve in-plant air quality, and decrease reliance on fossil resources. Many companies now favor adhesives with low or no volatile organic compounds (VOCs), thereby aligning their production operations with global sustainability goals and regulatory requirements. The sustainability trend in adhesives highlights how industry leaders are adopting greener formulas to achieve these objectives while maintaining or improving performance standards.

Common Challenges Faced with Industrial Adhesives

Despite significant progress in adhesive technology, manufacturers continue to face notable challenges. Highly variable or difficult-to-bond surfaces, for example, can undermine bond consistency and product quality. As product designs and materials evolve, adhesives must adapt to new performance expectations—rendering continuous research and frequent reformulation necessary. Practical concerns such as storage stability, safe handling, and convenient application also remain pivotal to the success of adhesive-intensive manufacturing operations. Addressing these challenges requires ongoing collaboration between adhesive suppliers and end-users to ensure solutions are tailored, effective, and reliable.

Quality Control and Testing Procedures

Effective quality controls are most successful when they mirror the conditions to which adhesives will be subjected in real-world applications. Manufacturers rely on stress and peel tests, as well as rigorous environmental exposure assessments, to ensure adhesives maintain their strength and integrity throughout a product’s lifecycle. These testing protocols help identify and mitigate potential issues—such as degradation in the presence of chemicals or UV light—long before products reach the market, significantly reducing risks of recalls and field failures.

Emerging Technologies and Future Outlook

Adhesive science continues to evolve, with research now centered around smart adhesives that incorporate self-sensing and self-healing characteristics. These adhesives can monitor structural integrity or even automatically repair minor damage, thereby extending product life and reducing maintenance needs. Additionally, predictive modeling and simulation tools enable researchers and engineers to fine-tune adhesive formulations before full-scale production, thereby saving time and resources. According to ongoing industry analyses from Forbes, these advances are poised to transform entire sectors by enhancing manufacturing efficiency and reducing environmental burdens.

Final Thoughts: Making Confident Choices in Adhesive Selection

Industrial adhesives quietly underpin much of the world’s manufacturing infrastructure. Understanding the trade-offs between strength, application speed, safety, and sustainability is crucial for engineers and procurement specialists striving to produce innovative, high-quality products. As new technologies and greener formulations emerge, staying educated about adhesive advancements is essential. In a rapidly shifting landscape, informed adhesive selection remains at the core of competitive, reliable, and responsible manufacturing.